In order to maintain efficiency and safety over time, it is necessary to carry out proper periodic maintenance of installations, as every item is subject to wear and tear.

Regular maintenance keeps installations and their components safe and reliable.

Lack of maintenance or inadequate maintenance can lead to dangerous situations.

A company must be able to prevent breakdowns, but also design and monitor an optimal management system capable of incorporating new available technologies.

When we speak of plant maintenance, we do not just consider the execution of certain works.

Maintenance is a plurality of activities, ranging from diagnostics to materials management, from information systems to documentation, from training of human resources to their optimal utilisation.

Maintenance must plan, organise and carry out interventions with the aim of ensuring the good condition of equipment during periods of operation by minimising downtime.

Without maintenance, safety is no longer guaranteed. Don’t wait for an accident to happen, book your maintenance.

Built-up back pressure

Certified (discharge) capacity

Chemical resistance

Cold differential test pressure

comparatore

Converter

Corrosion protection

documental management system

düsseldorf

exhibitions

flange

Flow area

fluid

Germany

hydrogen

identification plate

ISO 4126-1

Lift

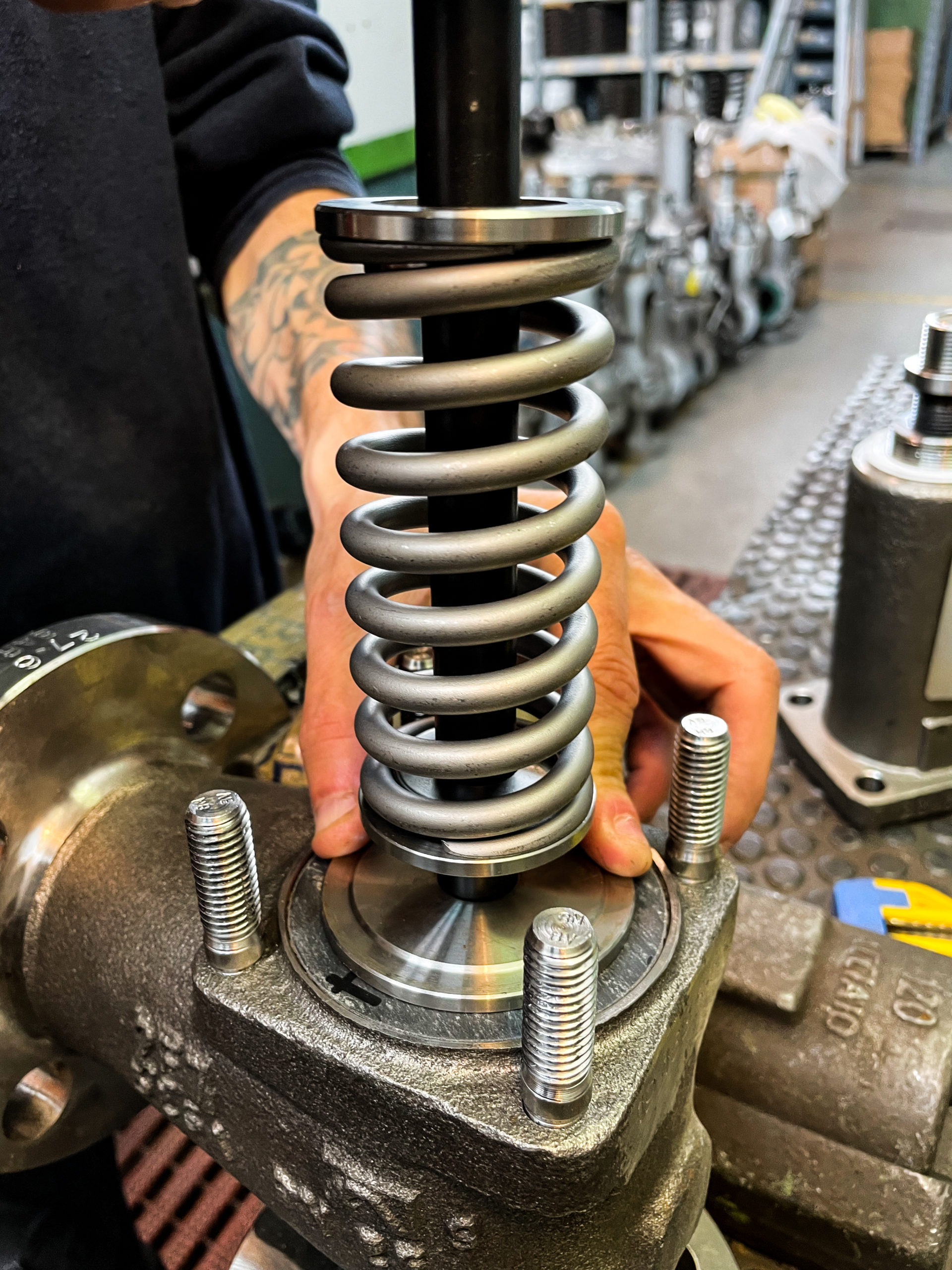

maintenance

manometro

Maximum allowable pressure

micrometro

misurazione

Non-stick properties

Overpressure

Perfluoroalkoxy alkane

PFA coating

PFA lining

Pressure

relief valve

Relieving pressure

Reseating pressure

Safety relief valve

Safety valve

safety valves

Set pressure

Superimposed back pressure

table

taratura

TERMS AND DEFINITIONS

trade fairs

User and maintenance manual

valve world expo

Viscosity

Wiki